KONDUCT®

Thermally/electrically conductive and EMI/RFI shielding compounds, masterbatches and additives

Thermal management, electrical conductivity/static dissipation and shielding solutions for plastic, rubber & silicone.

Why use conductive polymers?

With appropriate design & utilisation, conductive plastics can replace metals in many thermal management applications.

There is a growing demand for thermal management of components, devices and systems in established and emerging areas such as electronics, LED lighting and battery technology/e-powertrain.

Metals are traditionally utilised here for applications such as heat sinks, housings and covers, but there are drawbacks and limitations to their use and alternative materials offering new design advantages are increasingly sought after. Thermally conductive polymers are a potential candidate which, if designed and utilised correctly, can operate successfully in this arena.

Have a question? We are always happy to chat, so feel free to give us a call on +44(0)1495211400.

01.

Tailored thermal performance

Tailoring of thermal conductivity properties leads to enhanced performance from application specific materials.

02.

Weight reduction

Weight reduction leading to enhanced fuel consumption.

03.

Inherent corrosion resistance

Inherent corrosion resistance, enhancing product quality and lifetime.

04.

Component consolidation

Part consolidation opportunities leading to a reduction in number of components and costs.

05.

Design freedom

Capability to injection mould/overmould enabling design freedom and easier processing for more complex shapes.

06.

Electrically insulating or conductive

Potential to offer electrically insulating or conductive solutions, expanding the scope of possible applications.

In-house

Netzsch thermal conductivity analysis

Our Netzsch LFA447 laser flash (ASTM E-1461, DIN EN 821 and DIN 30905) accurately reports thermal conductivity of planar samples in both the through-plane and in-plane orientations.

Benefits of KONDUCT®

KONDUCT high thermal conductivity additives can be incorporated into a wide range of plastics, from commodity to high performance materials.

KONDUCT materials are available as electrically insulating or conductive options, and bespoke solutions can be developed to meet your specific thermal management challenges.

01.

Flexibility

With the on-site capabilities and facilities, Radical Materials are able to support small to large custom developments from lab scale all the way up to full production.

02.

Testing & Reporting

A wide suite of test facilities are available to support developments. These include mechanical tests as well as properties such as thermal conductivity and surface resistivity.

03.

R&D focus

A continuing focus on new and novel technologies to bring advantages and progression to conductive polymers.

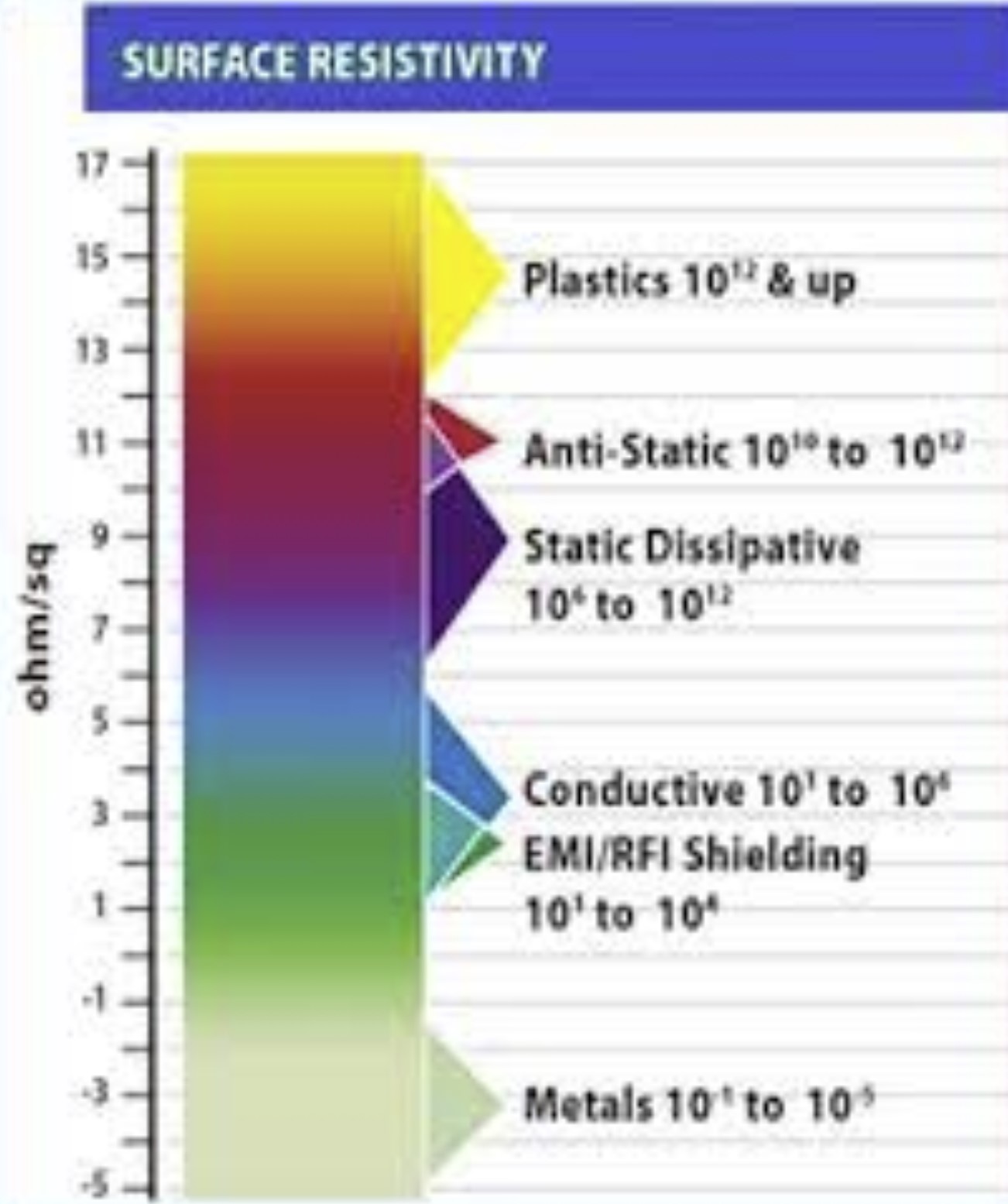

Electrical conductivity explained

Polymers are typically classed as electronically insulating materials and are often used for insulation applications in electrical devices.

However, there are many applications which call for traditional benefits of polymers over, for example, metals (low weight, no corrosion etc) whilst also requiring specific levels of electrical conductivity and/or shielding performance.

The below chart illustrates the range of surface resistivity required and possible between unfilled plastics, modified plastics and metals:

Thermal conductivity explained

Heat transfer occurs via three main mechanisms. When designing for thermal management and the control thereof, all of these mechanisms need to be considered as a whole, along with their effect on the entire system.

Through-plane

Up to

2.5

W/mK

In-plane

Up to

20

W/mK

01.

Radiation

Energy transfer away from an emitting source via electromagnetic waves. Can occur through a vacuum or solid/fluid.

02.

Convection

Energy transfer between a solid surface and a surrounding fluid (liquid/air). Such transfer is related to the conditions of the whole system in consideration and not to a specific material property.

03.

Conduction

Transfers heat via molecular collisions and requires physical contact. The process itself depends upon the existing temperature gradient, cross-section/dimensions of the component and the physical properties of the material in question (thermal conductivity).

When designing for thermal management and the control thereof, all of these mechanisms need to be considered as a whole, along with their effect on the entire system.

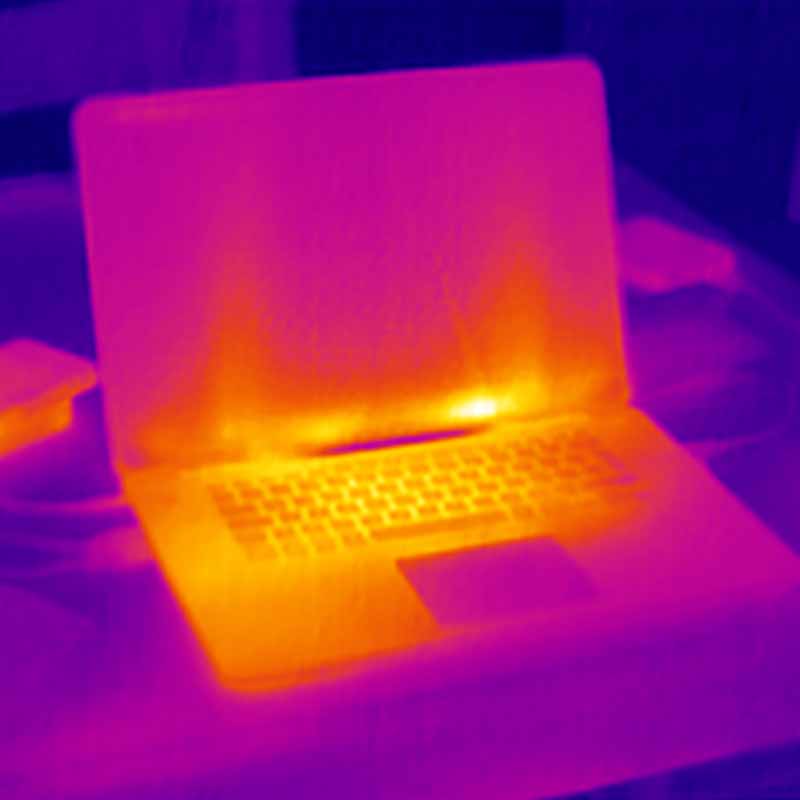

In-house

FLIR thermal video & imaging

Thermal video imaging allows us to easily visualise the difference in heat flow across a KONDUCT thermally conductive plastic compared with a standard plastic.

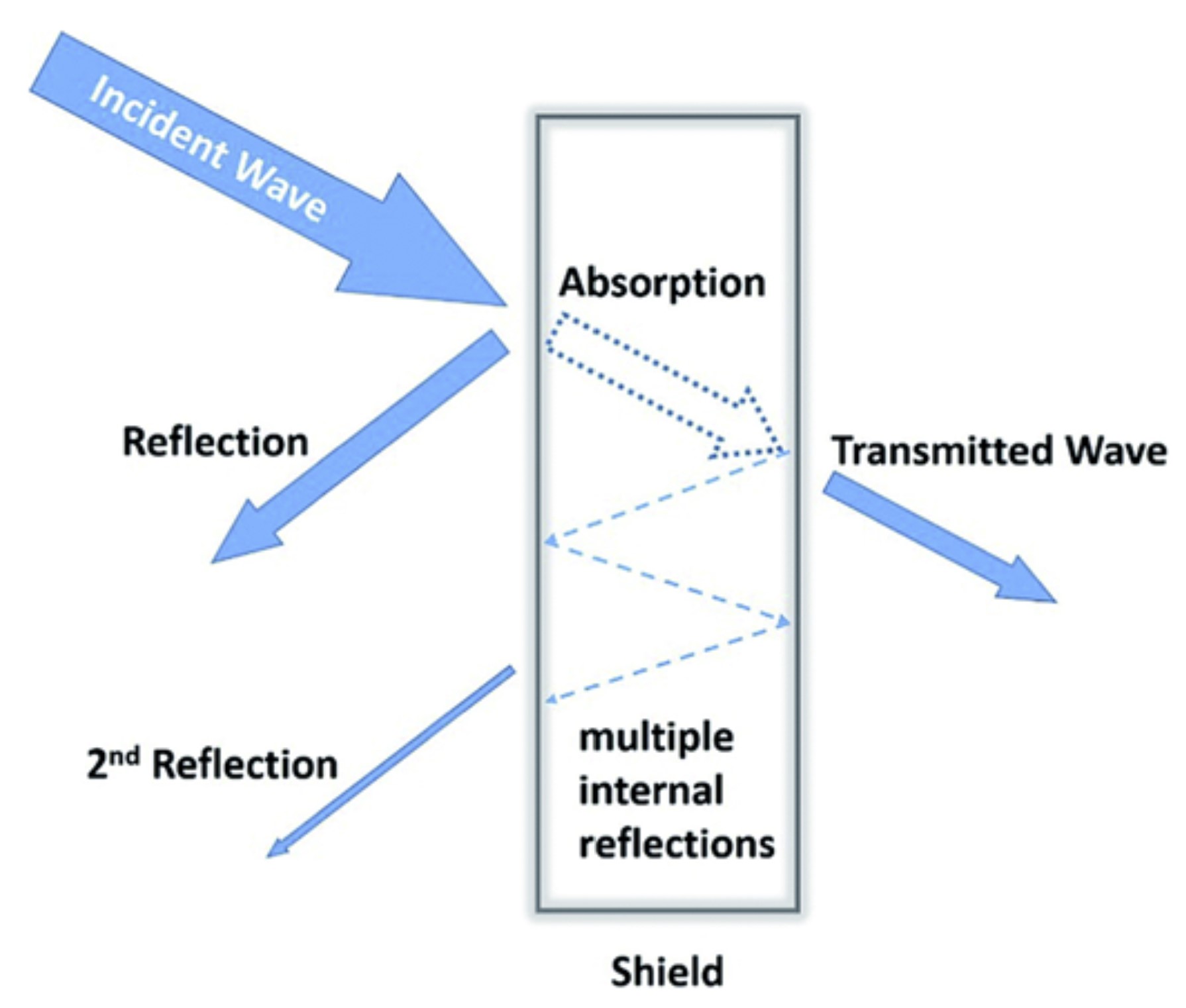

EMI/RFI Shielding

explained

Electromagnetic shielding is the practice of reducing the electromagnetic field in a space by blocking the field with barriers of conductive or magnetic materials.

Shielding is necessary to prevent mutual interference of devices causing disturbance or breakdown of operation, as well as protecting humans from associated health risks. EMI shielding (radio/microwaves) of both electronics and potentially the radiation source is becoming increasingly important to the high demands of today’s society.

When EM waves impinge on an object’s surface, they undergo one of three main mechanisms – reflection, absorption or transmission. In order to arrest the EM wave, it should be reflected or absorbed by the shielding material.

Solid metal components (Cu, Al, Ag, Ni) have traditionally been utilised successfully, but suffer from the drawbacks of high weight, susceptibility to corrosion and uneconomical processing. More interest now focuses on composite systems of typically an insulating polymer matrix with specific fillers. These fillers can include magnetic materials as well as electrical conductivity enhancers such as carbon nanotubes, graphene and structured carbon blacks.

Application examples

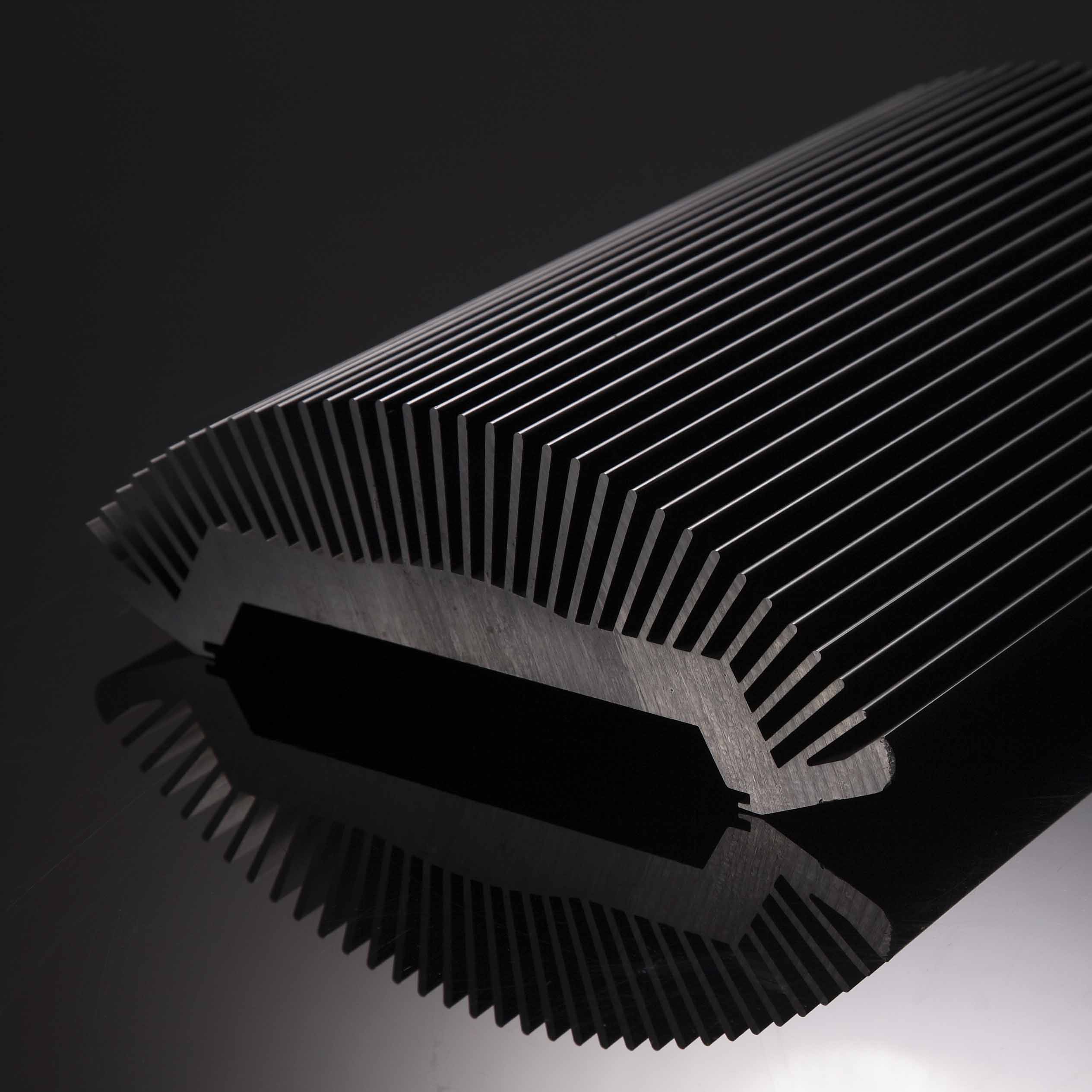

Heat sinks

In many applications, replacing aluminium or copper heatsinks with conductive plastics can increase production speed and reduce costs without compromising performance.

Mobile device heat dissipation

The ability to mould housings and casings from thermally conductive, electrically insulating plastics allows heat dissipation to be improved when use alongside, or even in place of, conventional metallic solutions.

Automotive & Aerospace

The rapid acceleration of electric vehicle adoption has brought with it an increased demand for thermal management solutions and weight reduction.

Bespoke product developments

Masterbatch and compound can be developed to suit specific requirements and applications.

A large proportion of our work is the development of custom solutions, often outside the scope of our standard product range. We relish a challenge, so feel free to test our capabilities..

01.

Research & development

With the on-site capabilities and facilities, Radical Materials are able to support small to large custom developments from lab scale all the way up to full production.

02.

Testing capabilities

A wide suite of test facilities are available to support developments. These include mechanical tests as well as properties such as thermal conductivity and surface resistivity.

03.

Certification

A wide suite of test facilities are available to support developments. These include mechanical tests as well as properties such as thermal conductivity and surface resistivity.

04.

Manufacturing

A continuing focus on new and novel technologies to bring advantages and progression to conductive polymers.

Frequently asked questions

We have endeavoured to provide a summary of the questions we're most often asked, but if you would like us to elaborate or have a different question, please contact us for assistance.

What is thermal conductivity?

The measure of a materials ability to conduct heat. Materials of relatively high thermal conductivity (metals for example) are commonly used for heat sink and thermal management applications whereas materials of low thermal conductivity (unfilled polymers for example) are used for thermal insulation.

What is electrical conductivity?

The ability of electric current to flow through a material. Metals typically have high electrical conductivity, whereas unfilled polymers typically show very low conductivity (high resistivity).

How can you add thermal and/or electrical conductivity performance to a polymer?

Engineered additives and additive blends are incorporated into the polymer during the compounding stage. Such additives can be based upon metals, carbon, ceramics, minerals etc and can be on the micro or nano scale (for example carbon nanotubes and graphene).

What type of polymer can be made thermally and/or electrically conductive?

Including but not limited to polyamide (PA), polyethylene (PE), polypropylene (PP), acetal (POM), thermoplastic polyurethane (TPU), PVC, ABS, polycarbonate (PC), polyester (PET/PBT), PTFE, silicone, natural rubber, NBR and SBR. Processing techniques can include injection moulding, extrusion, compression moulding etc.

Will the mechanical performance of the polymer be affected by introducing additives?

The mechanical properties of any polymer will invariably be affected by introducing additives. This can be engineered by careful control of the polymer system and the controlled use of property modifiers etc.

What can thermally and/or electrically conductive polymers be used for?

Applications in thermal management or requiring electrical conductivity, EMI shielding or static dissipation. Across sectors such as automotive, battery technology, electronics, lighting, aerospace/defence etc.

What is a polymer?

A material made of long, repeating chains of molecules. Common examples are plastics and rubbers.

What is the difference between thermoplastic and thermoset polymers?

Thermoplastics: the individual molecular chains are not strongly cross-linked and this allows the material to be repeatedly melted and solidified (think of candle wax or water/ice). Such behaviour allows for processing techniques such as extrusion and injection moulding. Common examples are polyethylene, polypropylene, nylon, polycarbonate etc.

Thermosets: the individual molecular chains are tightly cross-linked meaning once the material is hardened into a form, it will no longer melt or flow (think of boiling an egg). Common examples are bakelite, epoxy resin, polyester resin etc.