Material Testing & Analysis

Challenging materials to ensure optimum performance

Understanding the effect of functional additives on material properties

It is important to recognise that there may occasionally be unforeseen side effects when utilising functional additives. For this reason, we have invested in a comprehensive suite of material testing equipment, ensuring any such effects can be identified and mitigated as part of our standard process.

01.

Mechanical properties

Functional additives can often compromise the tensile and impact strength of polymers, particularly those which are typically used at high loadings such as metal/x-ray detectable or thermally/electrically conductive additives.

02.

Moulding parameters

While in many cases functional additives have little discernible effect on the processing of the polymer in which they are used, some can affect key parameters, such as melt flow.

03.

Environmental resilience

Some materials are employed specifically for their resilience in harsh environmental conditions. In these cases it is essential that any functional additive does not compromise their performance. UV exposure & weather testing can play a crucial role in the evaluation of such additives. UV-C testing is of particular importance for products used in healthcare enviroments, in which UV sterilisation is becoming commonplace.

04.

Flame retardancy

The flame retardancy of any material can be compromised by the use of functional additives and testing is critical.

Material testing

Tinius Olsen 10kN tensile tester

Tensile testing is a fundamental materials test in which a sample is subjected to a controlled tension until failure. The results from the test are commonly used to select a material for an application, for quality control, and to predict how a material will react under normal forces.

We use 10kN Tinius Olsen and 250N Mecmesin tensile testing machines and associated software capable of testing and reporting yield/tensile strength, modulus, elongation etc on a range of filled and unfilled polymers.

The information obtained from such testing allows for tensile characterisation of polymer samples and analysis of the effect of functional additives.

Tinius Olsen 10kN

Tensile tester

In-house material testing capabilities

We have a broad range of equipment to evaluate the performance of plastics & coatings, from challenging the impact strength at -30ºC to optimising the x-ray opacity of a detectable conveyor belt.

Tinius Olsen IT503

Charpy impact testing

Impact testing utilises the kinetic energy of a falling pendulum hammer to break a test sample, in order to determine the energy required to do so.

The resultant data gives a measure of impact toughness, and can be used to report comparisons between different materials and the effect of functional additives on this property.

Any additive can affect the mechanical strength of a material, and carrying out this testing in house allows us to really put our products (and yours!) through their paces.

Minebea Intec Dylight

X-ray inspection system

Our Minebea-Intec Dylight system is the perfect tool for assessing X-ray detectability of material samples against a wide range of food products.

Safeline twin-head detector

Metal detection system

The Safeline Metal Detection Equipment is able to assess the level of metal detectability of samples and compare to calibrated standards as well as benchmarking against other materials.

Taber Abrader

Elcometer 1720

Abrasion testing

Used to determine the resistance of materials or coatings to surface abrasion, typically through loss-in-weight calculations.

QLabs Q-UV UVA/B

QLabs Q-UV UVC

Accelerated weathering

UVC radiation is increasingly used for disinfection in food processing & healthcare environment where it can cause significant material degradation. While standard UVA/UVB tests remain useful, they provide no indication of the effects of UVC. For this reason, we recently installed a QLabs Q-UV/UVC specifically to challenge materials likely to be exposed to repeated UVC disinfection.

Labcold -30ºC freezer

35-90ºC water bath

Temperature challenge testing

For materials with low operating temperatures, testing at ambient conditions is of limited value. Our Labcold freezer allow us to subject material samples to mechanical testing at temperatures as low as -30ºC. Similarly, our two water baths enable accelerated ageing of materials & coatings prior to testing.

Material analysis

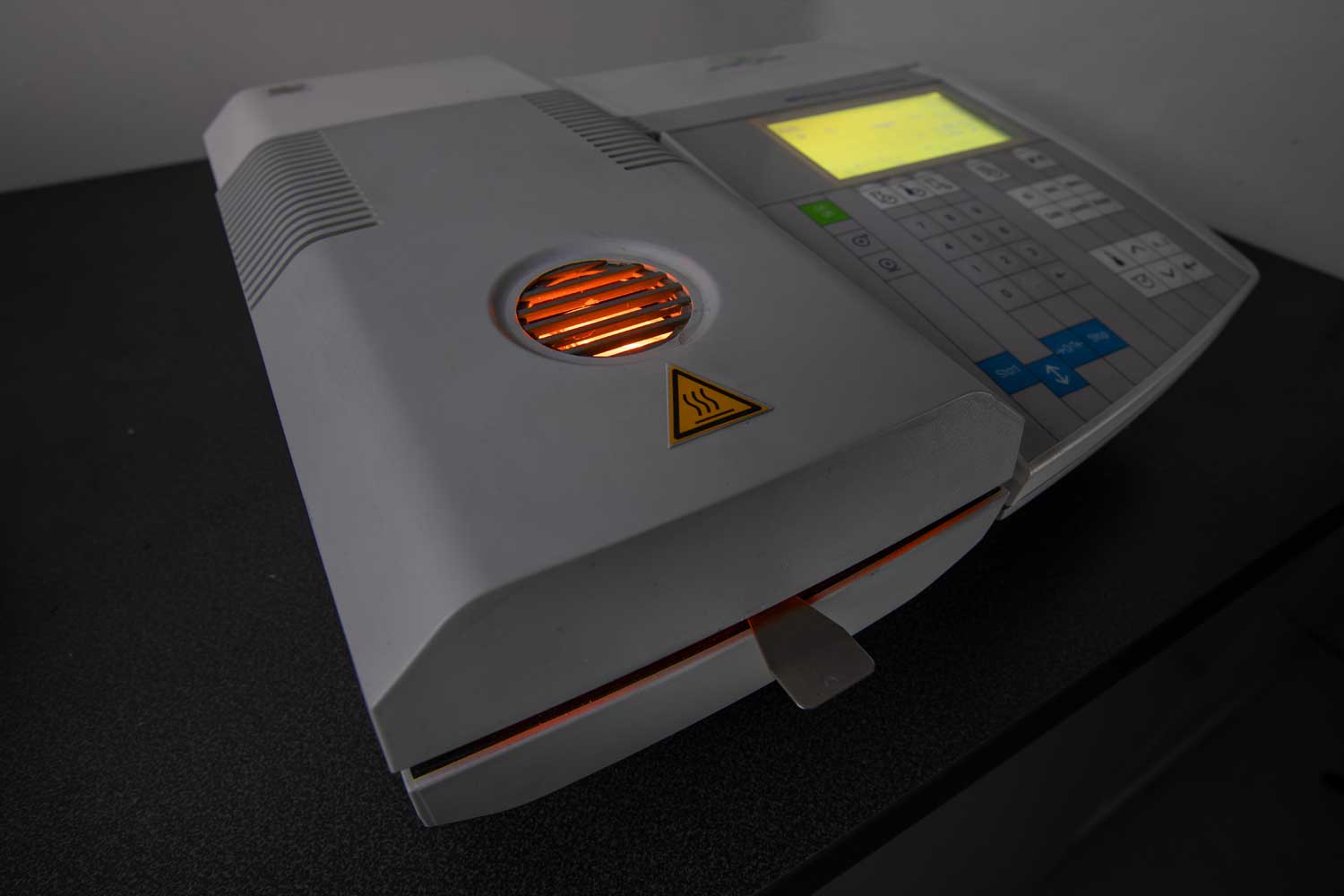

Netzsch LFA447 laser flash

Our Netzsch LFA447 laser flash (ASTM E-1461, DIN EN 821 and DIN 30905) accurately reports thermal conductivity of planar samples in both the through-plane and in-plane orientations.

In-house analytical capabilities

Netzsch LFA447 Laser Flash

Thermal conductivity analysis

Used to accurately measure thermal diffusivity and calculate thermal conductivity of planar samples.

Mettler Toldeo HR73

Moisture content analysis

Tinius Olsen

Melt flow analysis

A measure of the ease of flow of a polymer, most commonly used for quality testing, but also useful to ascertain the effect of additives on the polymer’s flow rate.

Furnace

Ash testing

High temperature muffle furnace to allow ashing of filled polymers and subsequent calculation of inorganic content.

KRÜSS Easydrop FM40

Contact angle analysis

Used to assess surface energy of materials.

GX ML3230B Materials Microscope

Microscopy with 4K imaging

Many of the additives we use are visible under high magnification. The GX microscope allows us to examine materials to evaluate additive dispersion.