Foreign body contamination in food products is a major area of concern for food processors/manufacturers. Examples of foreign body inclusions are fragments of metal, bone and glass as well as plastics and rubbers, which find their way into the food production chain from products/equipment/machinery used as part of the processing line. Should such foreign bodies pass through into the consumer chain, then there is significant risk to consumer health as well as huge financial and reputational implications to the manufacturers. Such incidents are reported in systems such as FSA (Food Standards Agency) report and RASFF (Rapid Alert System for Food and Feed).

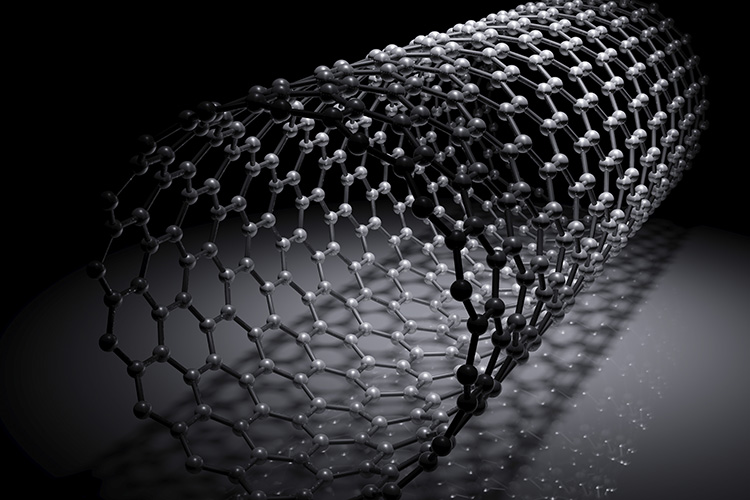

To combat the issue and comply with HACCP (Hazard Analysis and Critical Control Point) requirements, production lines will employ detection systems at critical control points, these commonly being metal detectors and/or X-ray systems. The difficulty with commonly utilised standard plastics and rubbers is that they possess neither the electrical/magnetic properties to be detected by metal detectors, nor typically the density to be differentiated from food products by an X-ray system. Standard plastics and rubbers are used extensively in machinery and products within food production lines and, as foreign body particles, are often totally undetectable by conventional systems.

It is possible to enhance the detectability of standard polymers, but early revisions relied purely on visual detection to try and prevent foreign body contamination. Polymer products were (and commonly still are) coloured blue to render them easier to visually detect on a food line due to the lack of naturally occurring blue in the bulk of food products.

Further enhancements around the design of filler/additive systems lead to the introduction of modified polymers, detectable by conventional metal detection systems. This still remains as probably the most common format of detectable polymer. A typical balanced coil metal detector consists of three coils, where the induced currents in the coil arrangement are in balance and generate an electro-magnetic field within the detector. This remains undisturbed until a metallic object passes through, causing a disturbance and triggering the sensor/alarm and rejection mechanism. The required additive system in such polymers must be specifically engineered to achieve the optimum response to industrial metal detectors at the lowest possible addition rate, such that other properties are not too significantly affected.

Moving on from metal detection systems, X-ray detectors are becoming increasingly popular in the food industry. Compared to metal detection systems, they have the advantage that they primarily rely upon density differences between food product and foreign body and hence are able to detect a range of additional foreign bodies such as glass, ceramic and bone. Once again, it is possible to engineer polymers such that they are potentially detectable against a range of food products via X-ray systems, but a different set of additive systems are applicable and, for optimum performance, this requirement needs to be treated separately to metal detection.

Polymer materials are and will continue to be used extensively throughout machinery, equipment and products within food processing lines. Components are typically manufactured by techniques such as injection moulding, compression moulding, extrusion or machining. Fragments of these polymers falling into the food line is a real risk and, without due consideration, such foreign bodies could pass through existing on-line detection systems and into the consumer chain totally undetected. There are potentially hugely negative implications to the food manufacturer should this happen. It is possible to modify existing polymers such that they offer strong levels of foreign body detection via either or all of the commonly utilised techniques on existing food lines (principally visual, metal detection and X-ray detection). However, there are many factors to consider up-front (type of polymer, final product, food products on the line, detection technique etc) and these need to be utilised fully and carefully when selecting or developing a well designed detectable polymer material.

If you are currently looking for a detectable polymer solution, please contact Chris Vince at chris@radicalmaterials.com or call us on 01495 211400.