Whilst it is always encouraging to see the positive effects of functional additives on the antimicrobial performance of a polymer solution, it is also important for many final applications to consider how the use of such additives might affect the overall mechanical performance of the base polymer.

Radical Materials have the in-house capability to mould test pieces from your exact compound or polymer/masterbatch combination and assess the influence of the additive on the base polymer performance via two principal methods:

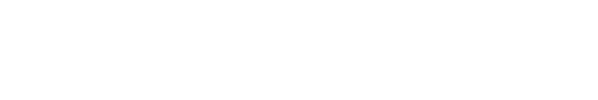

- Tensile testing – a fundamental materials test in which a standard specimen is subjected to a controlled tension until failure. The results from the test are commonly used to select a material for an application, for quality control, and to predict how a material will react under normal forces. Radical Materials utilises a 10kN tensile testing machine and associated software capable of testing, analysing and reporting on properties such as yield/ultimate tensile strength and elongation to failure etc. The information obtained from such testing allows for tensile characterisation of polymer samples and analysis of the effect of functional additives on base properties.

- Impact testing – utilises the kinetic energy of a falling pendulum hammer to break a standard test specimen, in order to determine the energy required to do so. The resultant data gives a measure of impact toughness and can be used to report comparisons between different materials and the effect of functional additives on this property. Radical Materials can perform testing and report to both Izod (test specimen clamped vertically) and Charpy (test specimen rests horizontally) test methods.

Whilst it is important to get an understanding of the impact of functional additives on the mechanical performance of base polymers, it can also be crucial to consider how external factors can affect the performance of the polymer solution in service. One such common influence is the effect of weathering, when components are utilised outdoors or simply exposed to UV light. The bulk of degradation of polymers in outdoor applications is caused by the effects of UV light and forms of damage can include colour changes, cracking, embrittlement, blistering etc.

Radical Materials utilises a QUV accelerated weathering tester to reproduce this damage and also accommodate for the additional impact of rain/dew. The system simulates the effects of natural sunlight using high intensity fluorescent UV lamps and is, in a few days or weeks, able to reproduce the damage that can occur over months of exposure outdoors. Visual changes can be quickly assessed against a reference standard and effects on mechanical performance confirmed utilising the test equipment described above.

It is important to recognise not only the positives functional additives can bring to a polymer solution, but also that there may occasionally be unforeseen side effects. It is also important to consider the effects of the operating environment on long-term performance. Aided by investment in a comprehensive suite of test capabilities, along with in-house knowledge and experience, Radical Materials can help to identify, and potentially mitigate, any such effects.