There is a growing demand for thermal management of components, devices and systems in established and emerging areas such as electronics, LED lighting and battery technology/e-powertrain. Metals are traditionally utilised here for applications such as heat sinks, housings and covers, but there are drawbacks and limitations to their use and alternative materials offering new design advantages are increasingly sought after. Thermally conductive polymers are a potential candidate that can operate successfully in this arena if designed and utilised correctly.

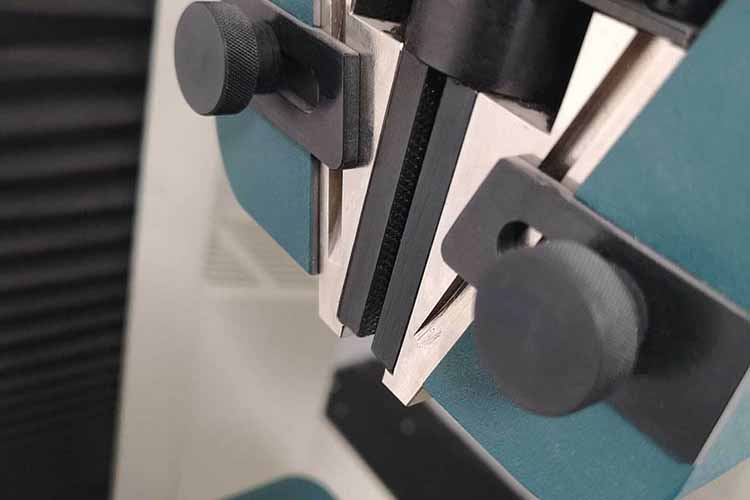

In order to take advantage of such benefits, the thermal conductivity of standard base polymers needs to be increased. Such an increase can be achieved by incorporating high thermal conductivity additives via compounding/mixing techniques. There are, however, many considerations in order to achieve a successful outcome. These include:

Particle geometry/aspect ratio – will affect overall thermal performance and can lead to anisotropy in the end components.

Particle size – an important factor influencing thermal performance as well as processing and mechanical properties.

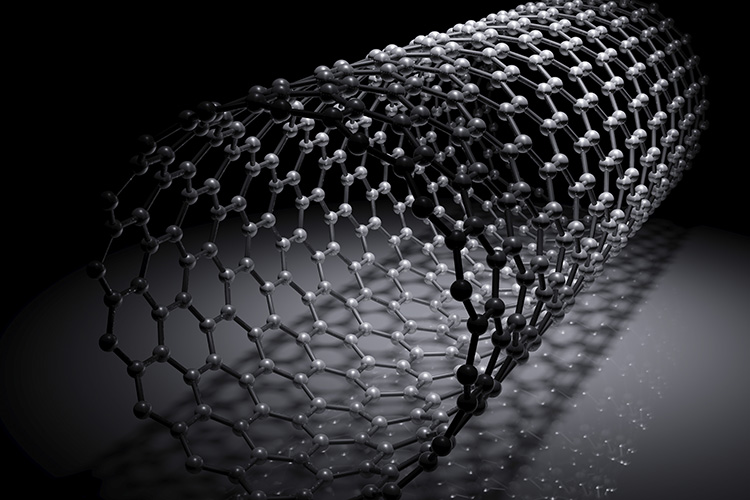

Electrical properties – additives can be divided into those that are largely electrically insulating (ceramics/minerals) and those with varying electrical conductivity levels (metals and carbon-based).

Addition rate – increasing additive levels will lead to a corresponding increase in thermal conductivity. However, this needs to be balanced out with the processability and

By careful consideration of polymer compound design, in conjunction with processing optimisation, operational conditions and final part design, thermally conductive polymers can potentially replace traditional materials such as metals in thermal management applications.